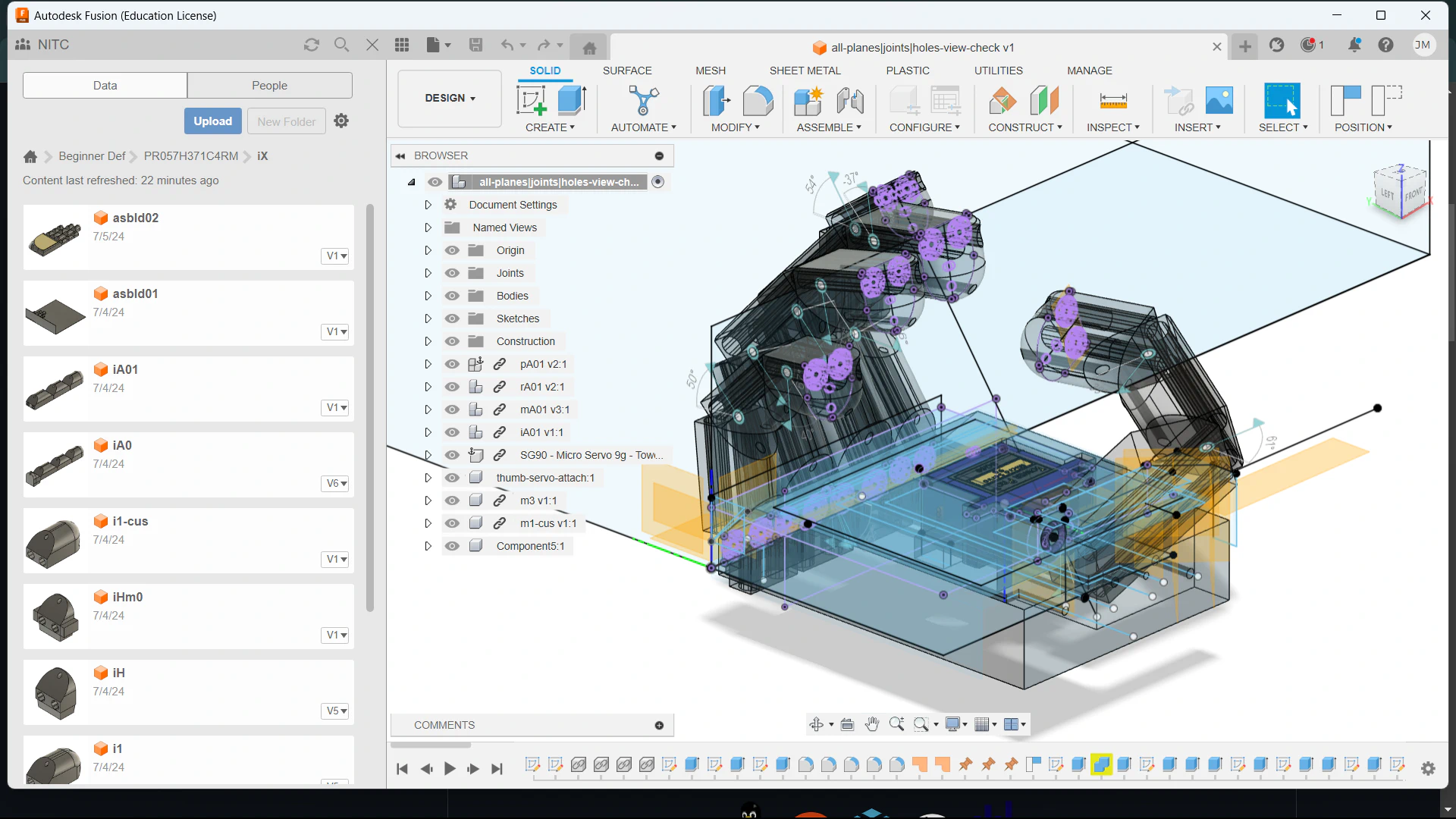

PR057H371C4RM

| Name | PR057H371C4RM |

|---|---|

| Description | A simple prosthetic arm that utilizes servo motors to create tension in strings, replicating the function of human tendons to achieve realistic finger motion. |

| Start | Ideation(2018), Implementation(Nov 2023) |

| Repository | PR057H371C4RM🔗 |

| Type | Individual |

| Level | Beginner |

| Skills | Mechanical Design, Programming |

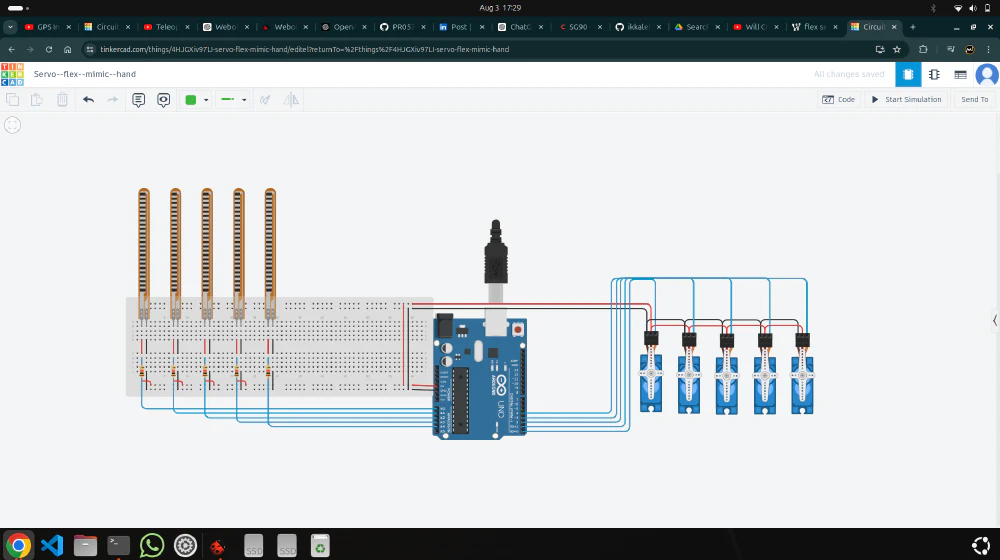

| Tools Used | Blender, Fusion 360, Tinkercad, Wokwi, VS Code, OpenCV, MediaPipe, Python, C++ |

| Current Status | Ongoing (Passive) |

| Progress | - Mechanical model complete with updated tolerances. - Finger tracking using MediaPipe is fully functional. - Servo control code is operational. |

| Next Steps | - Analyze weight distribution. - Reevaluate strength and agility for optimization. - 3D print and assemble the prosthetic arm. - Deploy the system on hardware. |

Overview

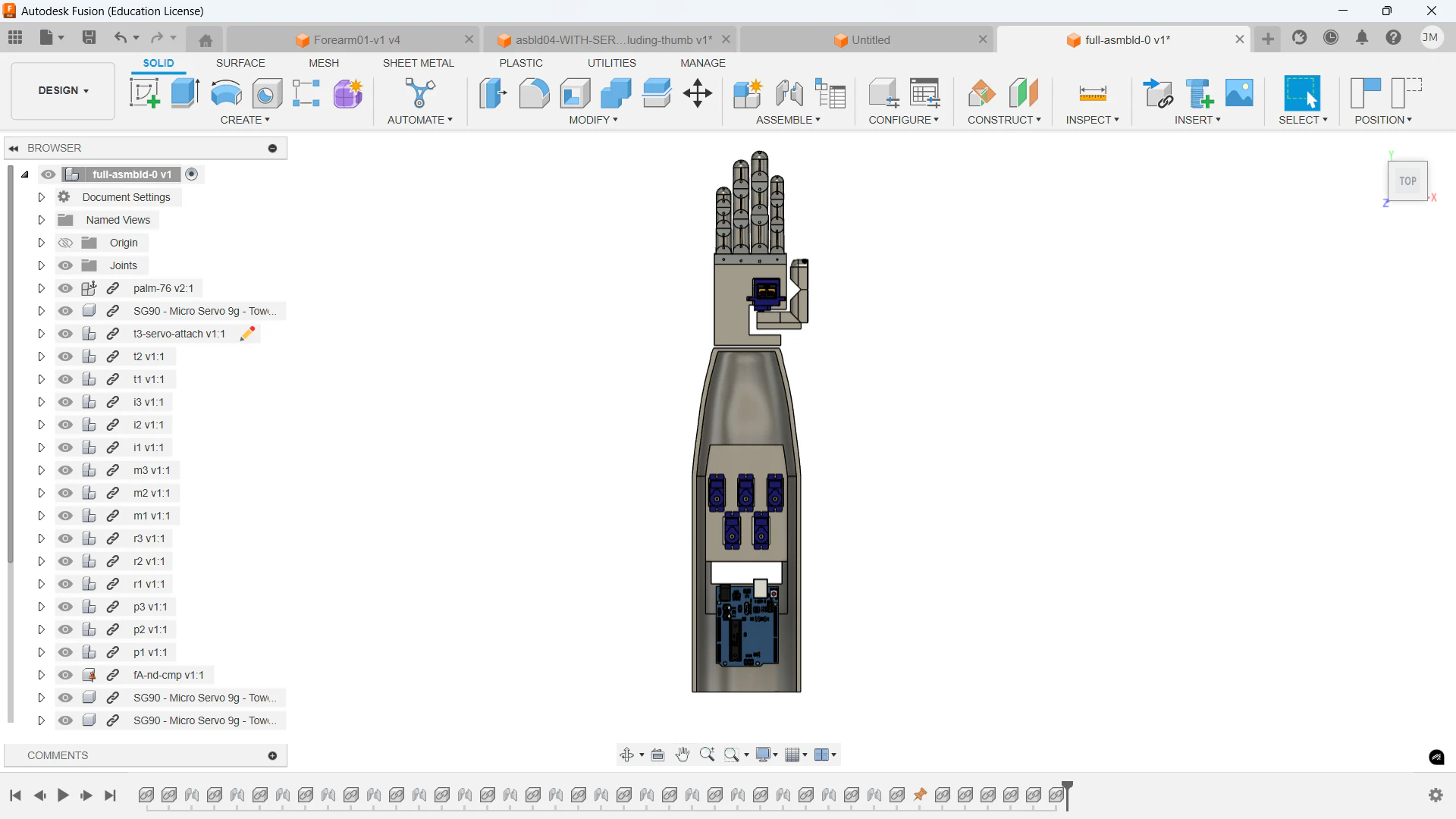

PR057H371C4RM is a biomechanical prosthetic arm designed to replicate the natural movement and structure of a human hand as closely as possible. The project focuses on affordability, accessibility, and precision in design, making it a viable option for those who need a functional mechanical replacement for a lost limb.

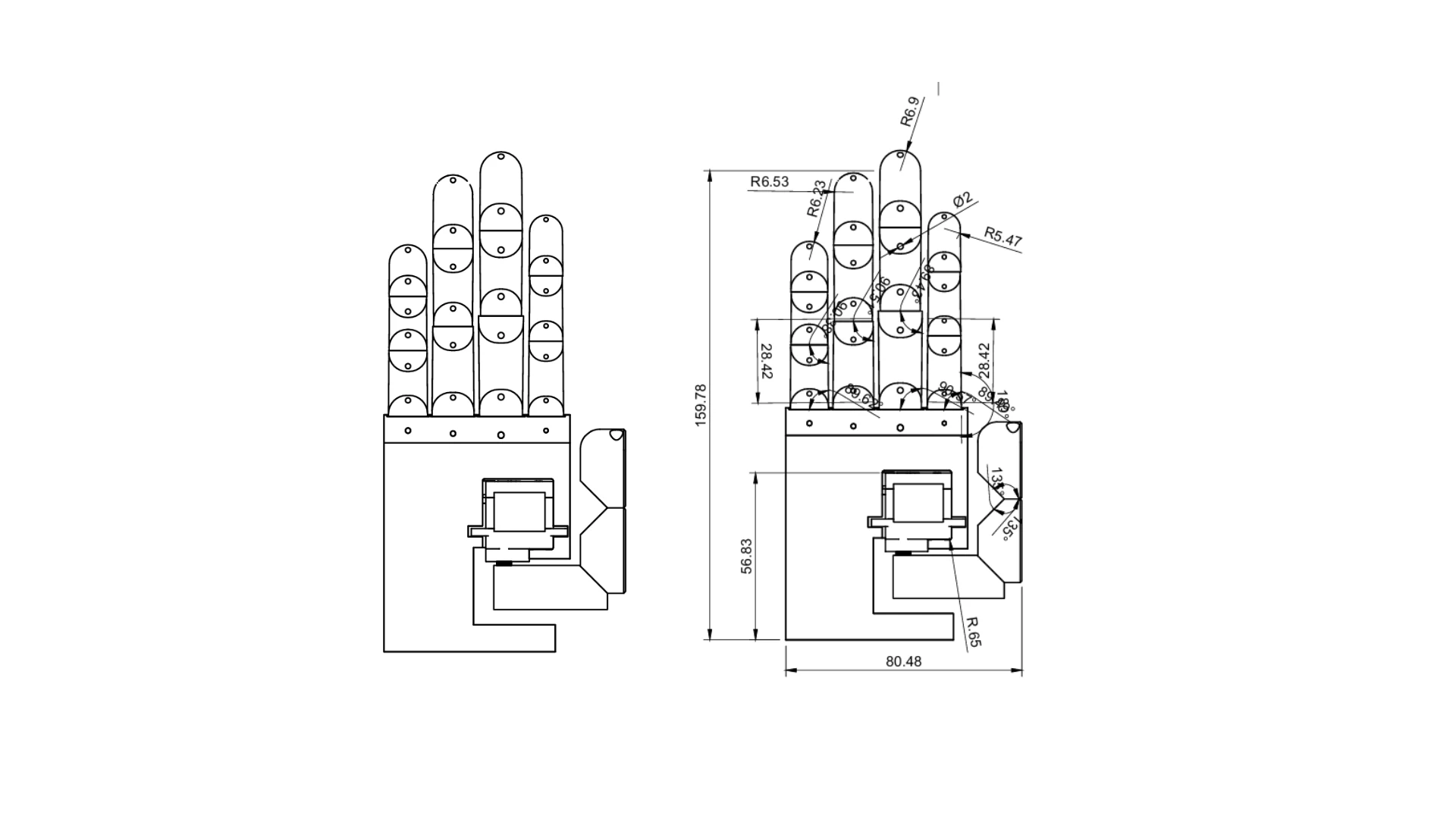

Each finger has been modeled with accurate anatomical proportions to mimic human biomechanics. The design incorporates tendons (strings), ligaments (rubber cords), and joints (pivot points) to replicate natural flexion and extension. The rubber cord system ensures the fingers return to their original position after movement, while servo motors control flexion, allowing for precise and lifelike motion.

This project has been my dream, inspired by my passion for animatronics and robotics. I discovered Will Cogley’s work on YouTube, which motivated me to learn Fusion 360 to model the entire hand from scratch. Due to budget constraints, I have not yet been able to fully 3D print and assemble the final prototype, but the design and simulation have been extensively tested.

Project Inspiration & Resources

- 3D Printing Service: Robu

- CAD Files:

- Project Inspiration: Will Cogley

- Bulk Export Add-ons: Project-Archiver

Demo Videos

Latest Prototype

| Motion Study | Assembly |

|---|---|

Here are few clicks

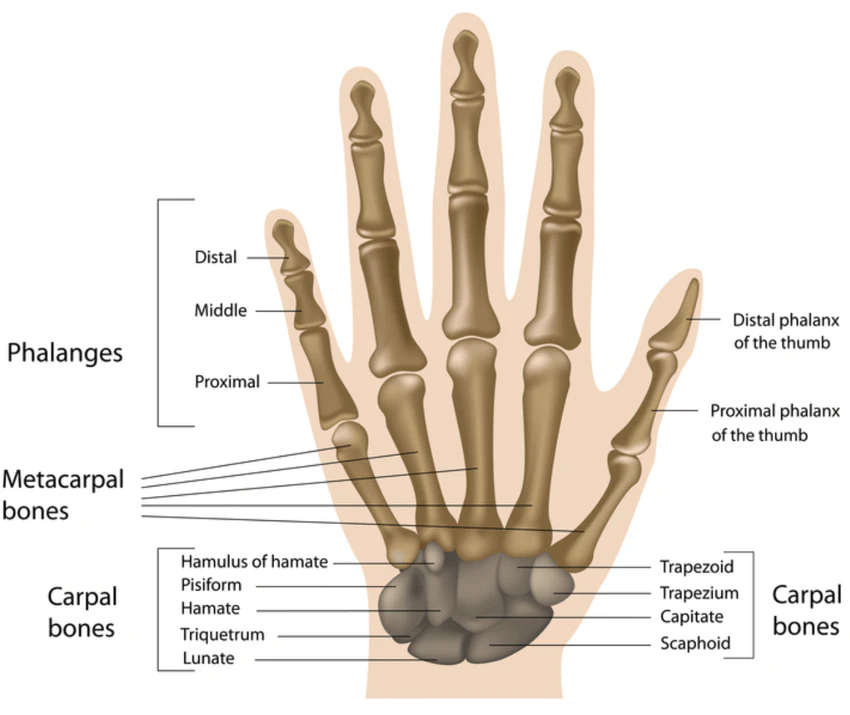

Hand Anatomy & Biomechanics in the Design

The prosthetic hand is designed to closely resemble the biological structure of a human hand, including key anatomical components:

Phalanges (Finger Bones) – Each finger consists of three segments:

- Distal Phalanx (tip of the finger)

- Middle Phalanx

- Proximal Phalanx (connects to the palm)

The thumb has only two phalanges (proximal and distal).

Metacarpals (Palm Bones) – The palm structure is designed to support all fingers and provide stability.

Tendons (Strings/Twine) – Artificial tendons run through the palm and wrist, connecting to servo motors in the arm.

Ligaments (Rubber Cords) – The rubber cords act like ligaments, maintaining the natural tension of the fingers.

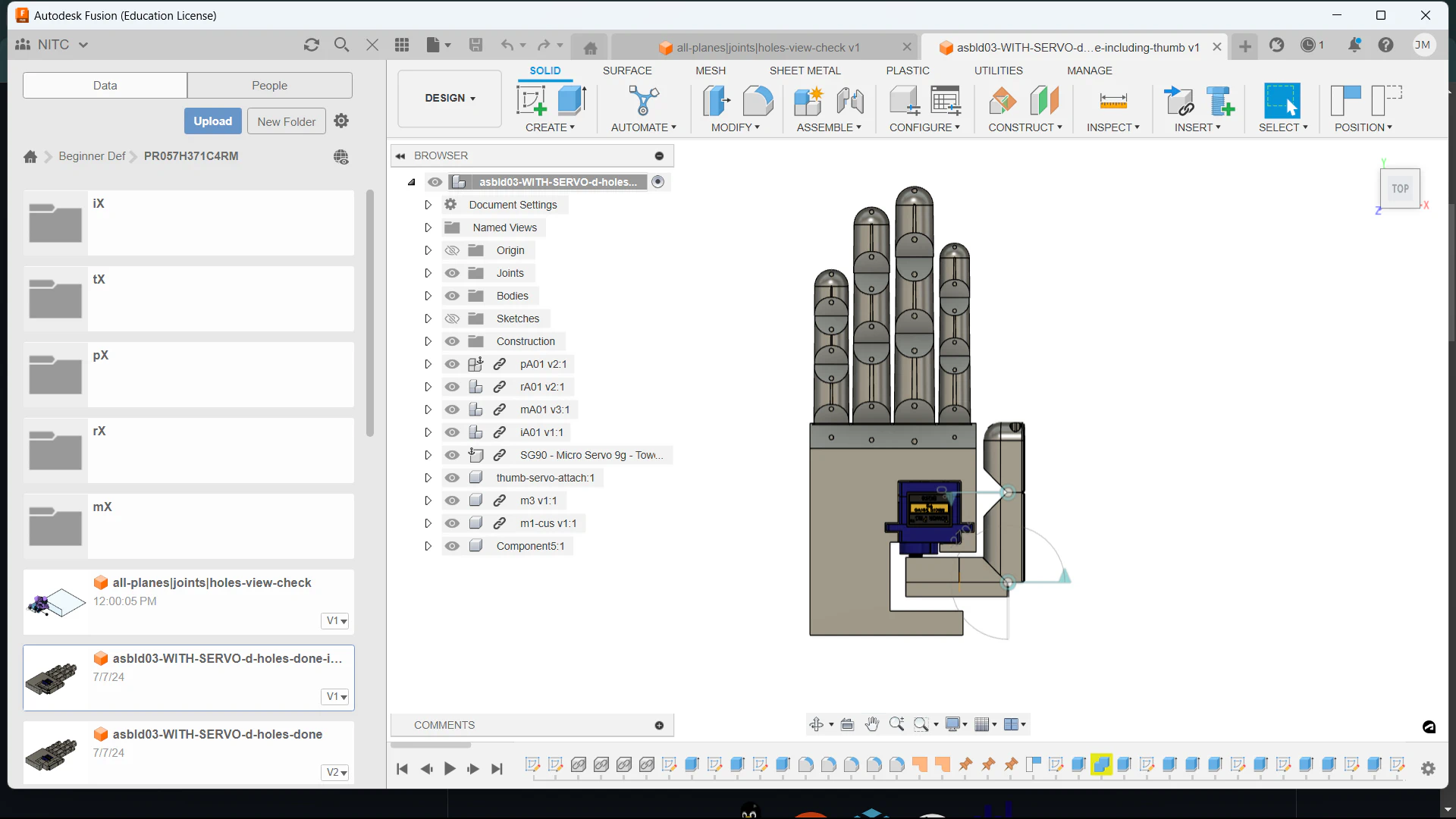

Finger Structure & Naming Convention

Each finger is labeled as follows:

IX – Index

MX – Middle

RX – Ring

PX – Pinky

TX – Thumb

Segment Breakdown

Each finger consists of multiple segments:

- IX (Index) → I1 (Distal), I2 (Middle), I3 (Proximal)

- MX (Middle) → M1 (Distal), M2 (Middle), M3 (Proximal)

- RX (Ring) → R1 (Distal), R2 (Middle), R3 (Proximal)

- PX (Pinky) → P1 (Distal), P2 (Middle), P3 (Proximal)

- TX (Thumb) → T1 (Distal), T2 (Proximal)

Segment Definitions:

- Distal (1): Fingertip section

- Middle (2): Intermediate joint section

- Proximal (3): Base section connecting to the palm (except for the thumb, which has only two segments)

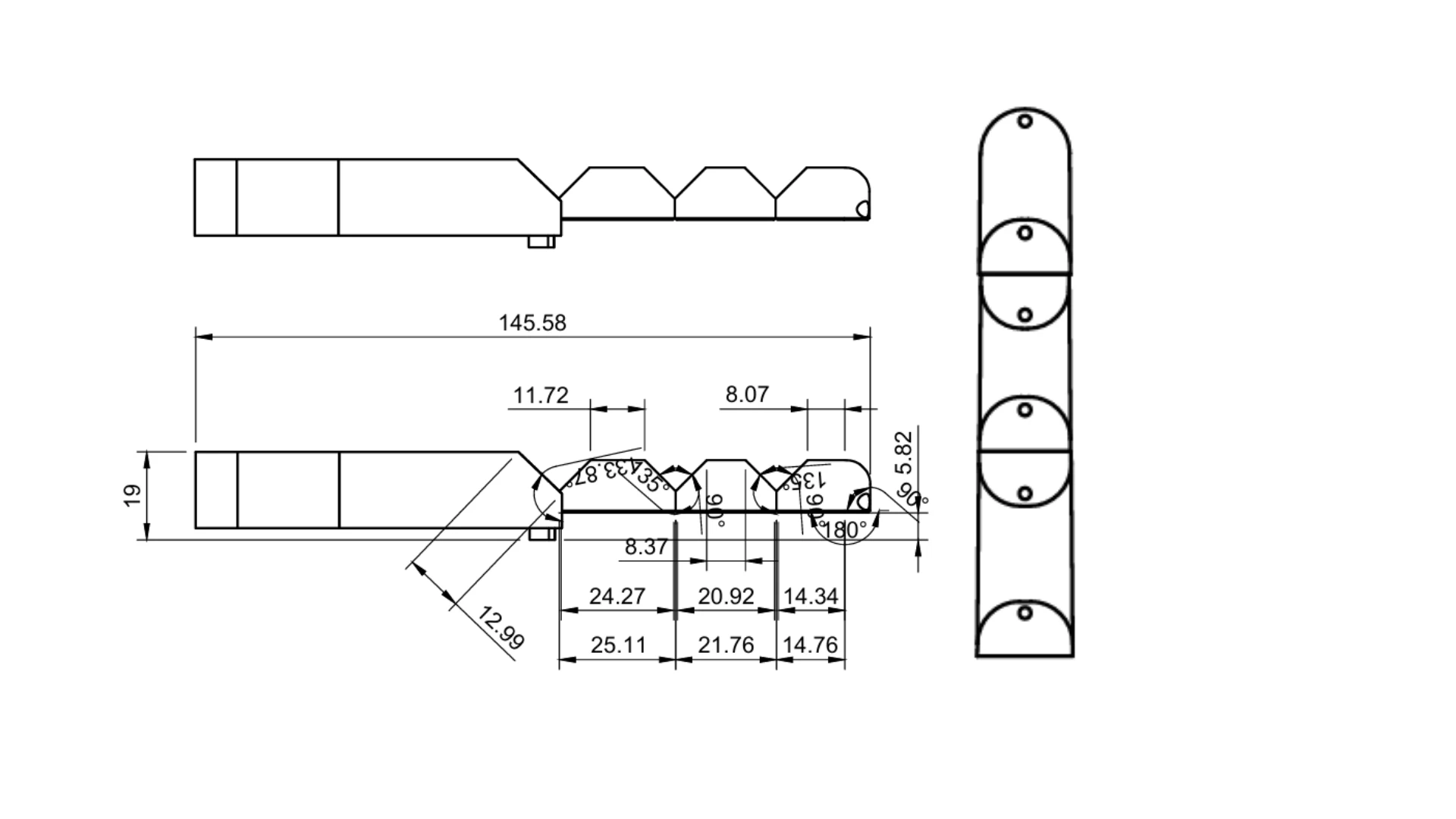

Finger Mechanism

Each finger consists of three segments connected by pivot points, allowing for natural bending and extension.

Rubber Cord System:

- A rubber cord runs twice through each finger, starting from the bottom, looping through the tip (making a U-turn), and returning to the bottom again.

- Both ends of the cord are secured at the back of the palm, ensuring controlled movement and restoring fingers to a neutral position.

String Control System:

- A string runs through each finger, with a knot at the fingertip to create movement when pulled.

- The strings pass through the palm, wrist, and arm, connecting to servo motors for actuation.

How It Works

- At rest, the rubber cords keep the fingers straight, aligning all segments.

- When a servo pulls a string, the corresponding finger bends.

- Once tension is released, the rubber cord returns the finger to its original position.

- Fingers can only move forward and back, preventing unnatural backward bending.

Thumb Mechanism

The thumb requires two independent servos for realistic movement:

- Palm Servo – Moves the thumb up and down (abduction/adduction).

- Arm Servo – Controls the folding motion (flexion/extension).

This dual-motor setup allows the thumb to grip objects naturally when combined with finger movement.

Palm & String Routing

- Holes in the palm allow rubber cords to be secured at the back, where the fingers intersect.

- Channels through the palm guide the control strings from the fingertips through the wrist to the servos in the arm.

Servo Control & Electronics

The system is powered by six SG90 servo motors controlled using an Arduino or similar microcontroller. The design allows for expansion with sensor-based or AI-driven control.

Simulation Links

Future Work & Goals

✅ Improve Mechanical & Electronic Design (70% Complete)

✅ Prototype & Testing Phases (20% Complete)

🔲 Enhance User Control via Muscle Signals (BCI) or Computer Vision (MediaPipe for Hand Tracking)

Next Steps

- Brain-Computer Interface (BCI): Connect the prosthetic arm to human muscles using electromyography (EMG) sensors.

- Computer Vision Integration: Use MediaPipe hand tracking to detect hand gestures and translate them into servo motor commands.

- Further Refinements in Mechanical Design & 3D Printing.

This project is constantly evolving, and I welcome feedback, collaboration, and new ideas! 🚀